As many medicinal products grow more complex, a growing number of drug developers are turning to dedicated manufacturing partners for support. These partners – Contract Development and Manufacturing Organizations, or CDMOs – can provide a wide range of development and production services for therapies delivered in many different ways.

One especially complex class of products is sterile injectables, which must be manufactured in a uniquely exacting way to ensure their safety and quality. If you’re developing one of these products, here’s a closer look at why it’s important to consider a specialized partner.

What makes a sterile injectables fill-finish CDMO uniquely valuable?

Medicinal products can have many different routes of administration: from pills taken orally to gels/creams applied to the skin, inhalable aerosol products, and sterile injectable products that can be delivered directly under the skin, into a muscle, or into the bloodstream.3

Some CDMOs serve as generalist manufacturing partners, offering support for many of these different delivery formats. But when it comes to injectables in pharma, dedicated expertise is critical.

Why? Since injectable medications must be completely free of contaminants, they must be produced through aseptic fill-finish, a technically demanding process that requires specialized facilities, technologies, knowledge, and training.

To offer fill-finish services for a sterile injectable, a CDMO must have all these resources ready to go – along with the many other systems needed to manufacture those products at the highest possible quality levels.

This kind of advanced support can be critical for a growing number of products that patients depend on. Let’s take a look at what kinds of products that includes, and why they’re increasingly important to the global healthcare system.

Product types an injectables CDMO can support

For millions of patients, sterile injectables are a critical component of their care. For many different reasons, this product class is one of the fastest-growing features of the entire global drug market: injectable therapies are expected to reach $1677.91 billion by 2030, up from $615.87 billion in 2021, thanks to a robust 11.78% CAGR.

Pharmaceutical and biologic injectables are also used to treat a wide and growing range of conditions, including:

- Ophthalmic products delivered into the eye

- Endocrinologic products to manage conditions like diabetes and obesity

- Neurologic products for conditions like migraine

- Rheumatology products for chronic conditions like rheumatoid arthritis and psoriasis

- And many more

While all these therapies have vastly different applications, and address very different patient needs, they all have one thing in common: they all benefit from the support of a CDMO with deep experience with the unique complexities and requirements of this product class.

A true injectables CDMO will have the infrastructure, supply chain, and processing expertise needed to manufacture sterile products, as well as the knowledge and resources needed to ensure those products safely reach patients in the most valuable format possible.

What services can this specialized partner provide?

A specialized CDMO can provide critical support for several unique areas of sterile injectables’ development and production – including numerous processes that are essential to their success.

Several of the key services include:

- Drug product development: Creating tailored aseptic manufacturing processes and identifying optimal container and packaging configurations.

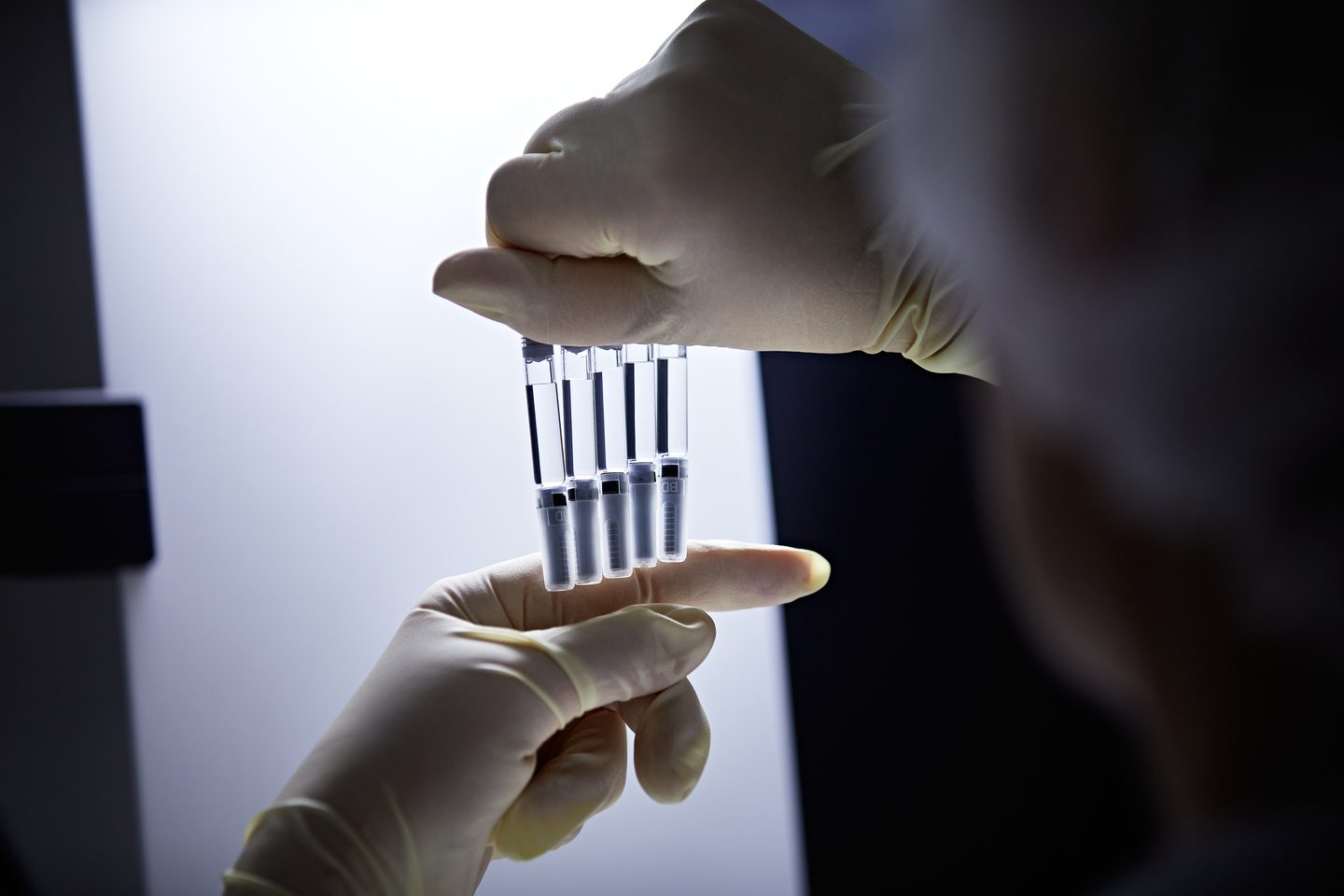

- Aseptic filling: Filling vials, syringes, or cartridges in a sterile environment that protects products from microbes, particulates, and other contaminants. Some sterile injectables fill finish CDMOs may offer services that are further specialized for products that need clinical-phase aseptic filling and commercial manufacturing support.

- Analytical services: Implementing and managing specialized testing methods designed to monitor and ensure product quality.

- Regulatory support: Navigating the many unique regulatory frameworks that may apply to sterile injectables in different markets.

- Device assembly & packaging: Developing customized carton and blister formats, as well as assembly process for delivery devices like autoinjectors and injector pens.

While generalist CDMOs may offer some of these services, they may not have the depth of experience or specialized knowledge required to support optimal results for a sterile injectable. For that, a specialized partner is often the best choice.

What should you look for in an injectables CDMO?

Beyond specialized expertise in aseptic fill finish, there are several other capabilities to look for in a CDMO that can optimally support your injectable drug product. Here are some of the aspects that are particularly important to evaluate:

Quality & regulatory systems

Look for a CDMO partner that has robust, well-established approaches to managing both product quality and regulatory oversight of that critical factor. That should include:

- Deep, current knowledge in regulatory targets and expectations in all your key markets.

- Established, documented protocols for achieving and maintaining quality specifications, including training, control strategies, and deviation responses.

- Detailed knowledge of ICHQ8-Q12 quality guidelines and how they should be implemented in an aseptic filling environment.

- A comprehensive digital chain of custody that protects the integrity of the process and product data they produce.

- Continuous regulatory monitoring and process evolution processes that can help you pursue cGMP compliance.

Proven track record

Prioritize CDMOs with a successful history of supporting sterile injectable products, protecting their quality standards, and navigating their pathways to market. This includes:

- Consistently successful audits by both customers and regulators, including the increasingly important pre-authorization inspections by authorities like the US Food and Drug Administration.

- Proven success with helping customers manage key transitions in their products’ life cycle, including lab-to-clinic scale-ups and initiating commercial manufacturing.

- Direct experience with a wide range of injectable molecules, substance classes, and delivery formats.

Strong product-partner fit

Carefully assess whether an injectables CDMO can support key aspects of your product and development strategy, including:

- Stability development strategies: Look for a partner that can protect the stability of frozen products via a robust cold chain, or offer integrated lyophilization services for extended shelf life.

- Analytical capabilities: Their analytical services team should be ready to confidently translate your testing methods to the CDMO’s own laboratories, and then consistently monitor and control your product’s quality [6] during its manufacturing cycle.

- Regulatory expertise: Look for extensive knowledge of regulators’ expectations and compliance frameworks for parenteral products, including both standalone medications and combination products.

- Resource availability: Resources and facilities should be available when you’re ready to start filling your product.

Sustainability strategy

If your organization is one of the many drug developers working to address its carbon footprint, supply chain partners should play a key role in helping you achieve your overall sustainability targets. So look for a partner that has:

- A deep and demonstrated commitment to optimizing the ecological impact of their own operations.

- Sustained initiatives dedicated to managing down their carbon footprint.

- Active programs for developing containers, assembly, packaging, and sterilization processes that are less resource-intensive.

Can they evolve with you?

As you explore your partnership options, remember to think beyond your current needs as well: Look for an injectables CDMO that can not only help you meet your biggest immediate milestones, but also support you as far through the product life cycle as you plan to own your product.

Switching development and manufacturing partners can be a time-consuming and cost-intensive process. A careful, strategic choice now can save you many potential challenges downstream.

Exploring CDMO partnerships? We’d love to connect.

Finding the right CDMO is just the first step. Building a strong, collaborative partnership is key to navigating the challenges of injectable development and ensuring the success of your product.

We take pride in being one of the world’s top injectables CDMOs, with 40+ years of global experience across a wide range of products and substance classes. Reach out today to discuss how we can support you and your sterile injectable product.