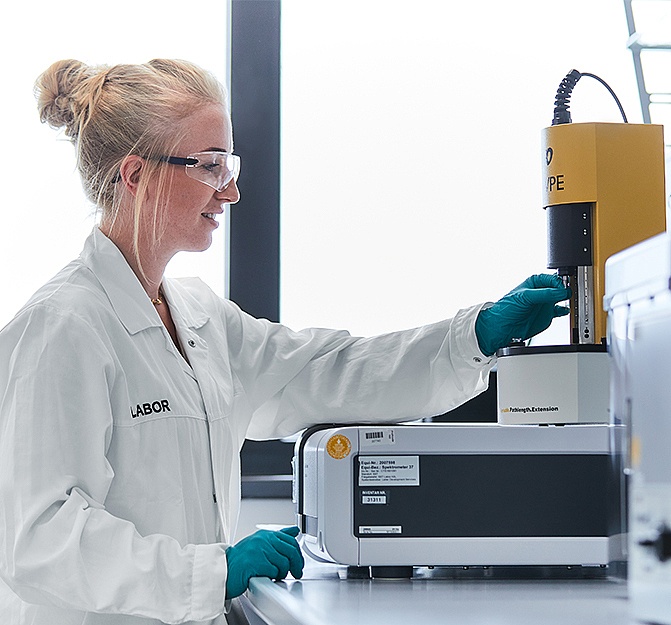

cGMP-compliant testing of incoming materials

When we receive raw and starting materials, our quality experts follow rigorous protocols to ensure that the correct products have been delivered and that they meet established specifications for their intended use. Take a closer look at how we sample and test your excipients, packaging material, and other ingredients.