How I came to Vetter

I worked as a process engineer and specialized in quality assurance. In 2016, I applied to Vetter because, coming from the plastics sector, I wanted to explore new opportunities, develop myself, and learn about the pharmaceutical industry. Since then, I’ve been working in the Quality Control laboratory, where I investigate complaints and determine their causes.

My responsibilities in Quality Control

There are a number of reasons why products end up in our complaints department. More often than not, we can trace it back to improper usage. Damage can also occur during transport, improper storage, or subsequent processing. Like when customers package the syringe, or when it is handled by the staff in the doctor’s office or in the pharmacy, for example. We have extremely strict control systems that demand error-free processes, which is why internal complaints are less common than complaints from the market.

How we work in the lab

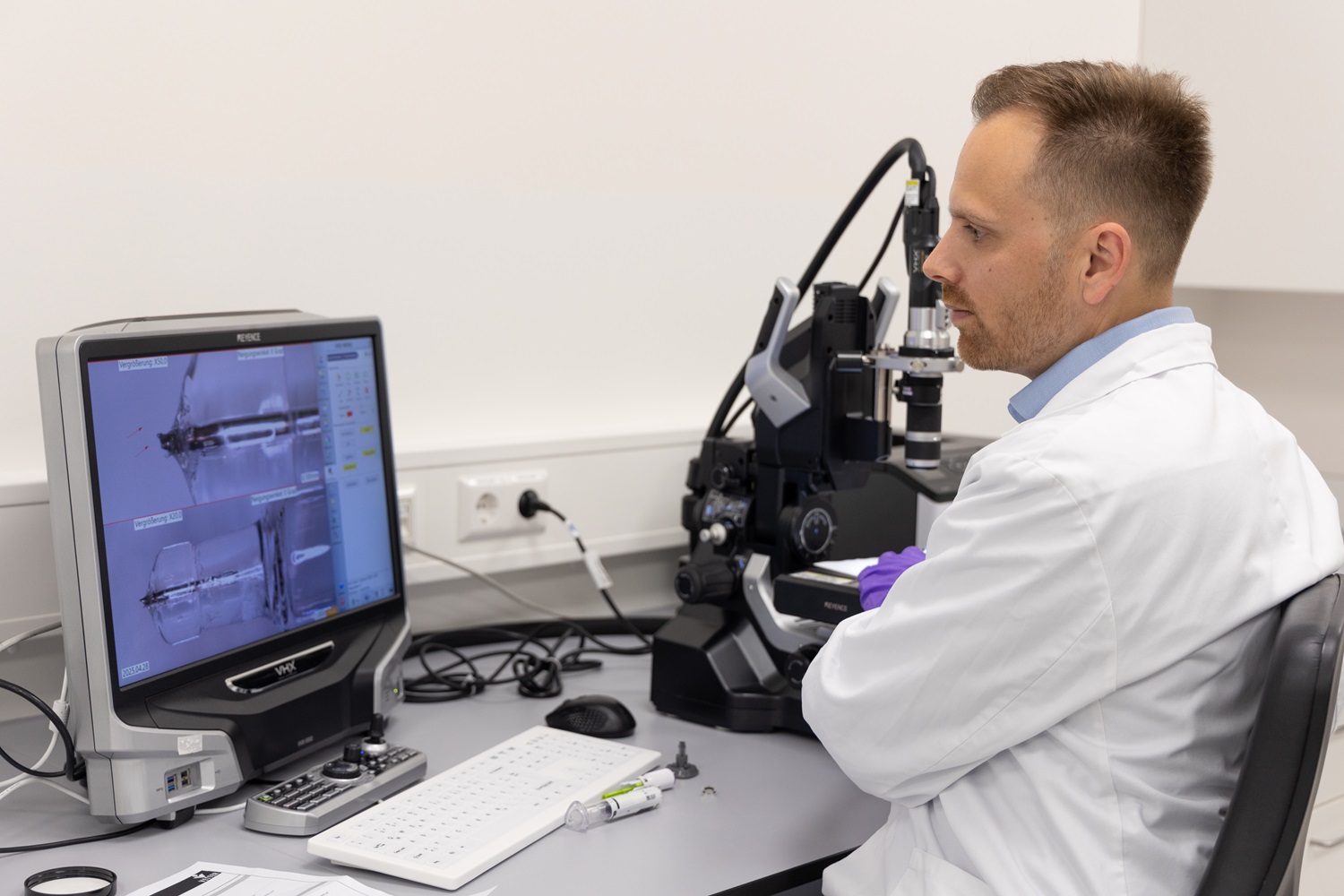

When we receive a damaged cannula for assessment, we begin our analysis. Is the tube bent or broken? Did the glass break due to tension or impact? Was it perhaps caused by an external force? Working with pharmaceutical products means having a huge responsibility, and it’s essential to investigate the root of the problem. It’s the only way for us to draw the right conclusions and ensure product quality and guarantee customer safety and satisfaction.

To do this, we analyze the samples under a digital microscope. We use a variety of measurement methods to trace, step by step, where and how exactly the defect is likely to have occurred. We analyze liquids, measure the contamination, and perform functional and leak tests. We document our lab work with images and videos. Just like criminologists, we then compile investigation reports that describe the facts and results and identify probable causes in a traceable manner.

Laboratory work is anything but mundane

Each complaint is its own unique, separate case, which makes the work so exciting. Over the years, you accumulate a wealth of chemical and physical knowledge, notice certain patterns related to where the samples came from, and connect with coworkers from all different departments.

We typically analyze about five samples per day. Usually, we arrive quickly at the results, but sometimes it can be tricky. That's when our experience comes in handy. We have access to innovative and precise measuring instruments. If there are any doubts, we send our samples to external specialized laboratories that can saw open cannulas[PL1] and take X-rays, for example.

What do you like about your job?

Working in our lab is really exciting. I appreciate the variety as well as the opportunity to interact with people from different departments and hierarchies. I’m delighted to have gained such valuable experience through conducting investigations and by working with others.

Would my job be something for you, too?

Those interested in working in Quality Control should be reliable, independent, responsible, and be able to put themselves in the user’s shoes. How was the medication used? What could have happened? Most of this can be taught, however. Each insight brings your further.