Sterile means sterile: The challenge of servicing aseptic manufacturing infrastructure

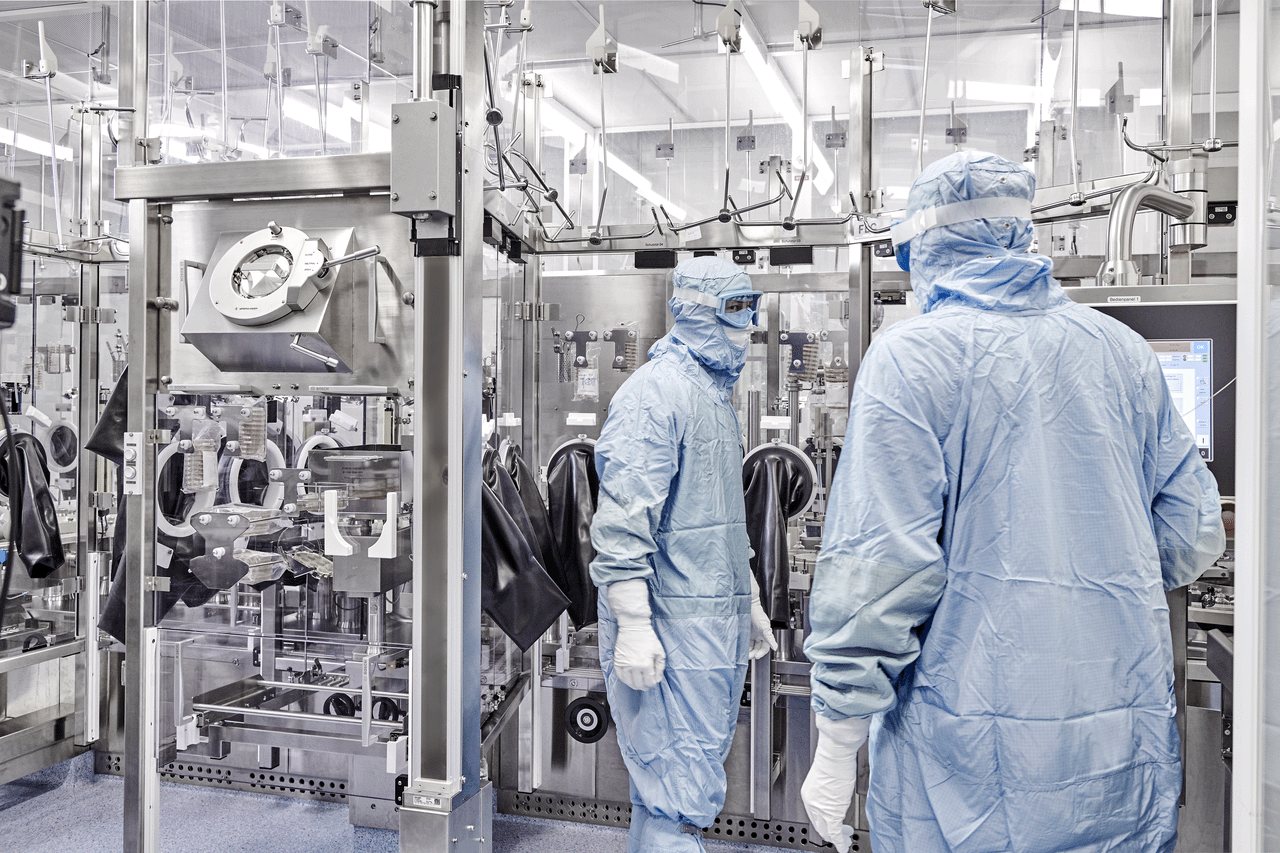

In aseptic manufacturing, maintaining cleanroom sterility is critical for CDMOs striving to provide a consistent global supply of their customers' vital products. Continuous equipment monitoring and efficient machinery maintenance are essential to that goal, helping to prevent potential contamination, GMP deviations, and costly, disruptive downtime.

While Vetter’s aseptic filling infrastructure already meets the high standards for sterility, productivity, and uptime, we’re continually exploring new ways to advance our operations. This proactive approach guided our recent investment in the “Maintastic” system: a cutting-edge digital platform specially adapted to this environment’s unique maintenance, repair, and breakdown management needs.

Streamlining a complex cleanroom service concept

The platform directly addressed several common service challenges encountered by aseptic manufacturers like Vetter:

- Minimizing cleanroom traffic: Recognizing that each entry into a sterile environment elevates the risk of potential contamination, Vetter sought a solution that could maximize technicians’ impact while minimizing their need to physically access cleanroom equipment.

- Connecting troubleshooters in multiple locations: In aseptic filling facilities, service workflows often span multiple production areas, separate technical infrastructure, and office areas. The new digital service system needed to seamlessly connect all these locations.

- Centralizing production support knowledge: With Vetter’s specialized filling machinery, maintenance, repair, and breakdown management all require extensive contextual and historical understanding, as well as ready access to maintenance records and technical specifications. Our service teams needed an accessible and intuitive method for accessing, searching, and sharing this critical knowledge.

Maintastic addressed each of these challenges with a unique proficiency in digitizing complex, highly regulated manufacturing infrastructure. Their approach fostered a close partnership between their development team and our in-house experts as we jointly customized the system for our specific needs.

The outcome: a tailored system that brings a new level of efficiency, control, and scalability to our production support operations.

Eyes in the cleanroom: Key components

For Vetter, implementing this system was more than a simple software upgrade: it was a strategic investment in empowering service teams with sophisticated remote monitoring capabilities, optimized workflows, and an intelligently organized knowledge repository. We're enhancing our ability to maintain critical production equipment, enabling faster responses that help minimize downtime.

The customized deployment incorporates several vital features that enable us to achieve the highest possible performance in our service and maintenance, repair, and breakdown management activities:

Virtual cleanroom access

One key component of the system: Enhanced remote visibility into the most tightly controlled zones of our production facilities. Custom H₂O₂-resistant tablets now enable real-time collaboration from outside the cleanroom, significantly reducing the need for physical entry into these sensitive areas.

Through live video and augmented reality capabilities, personnel inside the sterile environment can easily connect with service technicians outside the cleanroom, clearly describe and visually present any equipment issues, and draw on support from remote experts.

Compliant one-way ERP integration

With our customized version, master requirements, taxonomies, and datasets in our SAP system are efficiently and unidirectionally pushed from our ERP to our service management platform—keeping service team users consistently and compliantly aligned with all organizational frameworks. Leverage the SAP interface for workflows helps keep all relevant master data appropriately filtered and up to date.

This smooth, one-way flow of information provides automatic updates and maintains consistent data structures, terminology, and object names across our maintenance operations.

Cloud-based knowledge management

The deployment also features a detailed, structured, and user-friendly knowledge base for our service teams. It provides a protected access from anywhere, enables easy navigation and filtering, and allows seamless integration of new and historical data.

Being fully cloud-based, the new hub also enables maintenance personnel to collaborate in real-time across different locations, facilities, and teams. Teams in our administrative offices, technical areas, and cleanrooms can now share the same real-time view of vital maintenance knowledge.

Together, these features help empower our workforce to maintain the high levels of operational continuity. The system enables even greater responsiveness, adaptability, and efficiency across our maintenance and repair processes, and further equips our service teams to support consistent uptime and predictable production levels.

It’s one more way we’re investing in the protection of the global supply of our customers’ products

Above all, this innovative system highlights our continual commitment to reliable production of vital parenteral medications—and to helping maintain the worldwide flow of those products to patients in need.

For more on our investments in digital innovation, connect with one of our experts to learn about our world-class filling infrastructure and how it can support your next project.