Developing customized processes

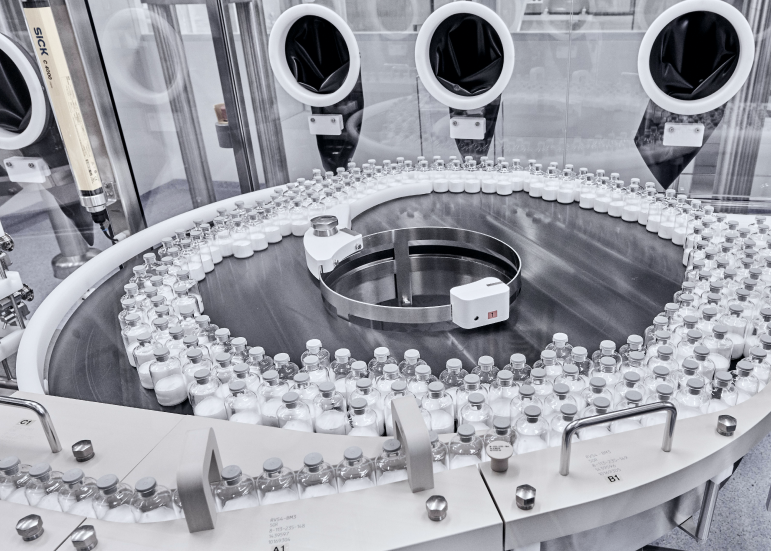

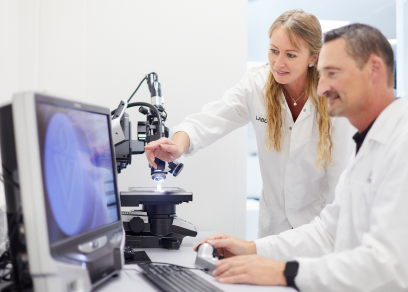

From the start of our partnership, we focus on laying a foundation for your product’s future success. Take a closer look at how we develop efficient, reproducible and scalable manufacturing processes that are fully optimized for your compound characteristics, target patients, and life cycle strategy.